- Scalable Synthesis of CO2-Selective Porous Single-Layer Graphene Membranes

Nature Chemical Engineering

(2025)

Author: Jian Hao, Piotr Mieczyslaw Gebolis, Piotr Marcin Gach, Mojtaba Chevalier, Luc Sébastien Bondaz, Ceren Kocaman, Kuang-Jung Hsu, Kapil Bhorkar, Deep J. Babu & Kumar Varoon Agrawal

Abstract

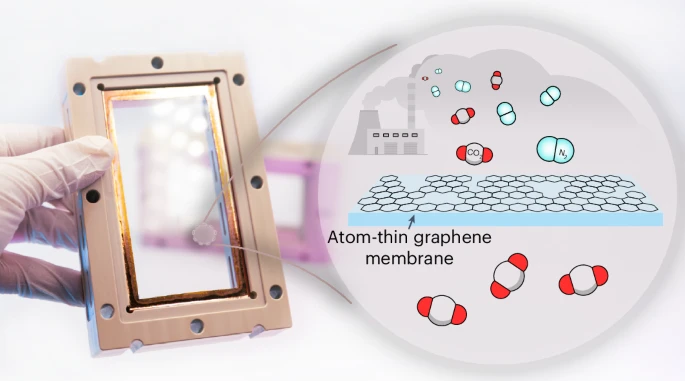

Membranes based on atom-thin porous single-layer graphene (PG) have shown attractive performance for diverse separation applications, especially gas separation and carbon capture. However, despite a decade of research, a scalable synthesis of PG membranes has remained under question. The literature on gas separation using porous graphene membranes is based on complex methods that limit membrane size and reproducibility. Here we introduce several interventions that substantially reduce PG membrane cost, allow uniform pore formation in a large area and enable the preparation of large-area PG membranes with attractive performance. We show that mass transfer of the oxidant plays a crucial role in achieving uniform oxidation of large-area graphene. Crack formation during the transfer of graphene, which also limits reproducibility, is eliminated using a protocol that does not require delicate floating and handling of graphene, allowing the realization of a high-performance 50-cm2 graphene membrane in a cross-flow module.

Main

Nanoporous atomically thin membranes (NATMs) have emerged as a promising platform for effectively separating molecules and ions, exploiting mass, size and affinity differences. Despite progress on the fundamental aspects of NATM, including transport mechanism, pore incorporation and membrane fabrication, this field faces an outstanding critical challenge on the scalability of NATMs. The most popular and studied NATM is porous single-layer graphene (PG). The successful incorporation of carbon dioxide (CO2)-selective pores in PG has led to attractive performance for carbon capture. This involves selective separation of CO2 from nitrogen (N2). It is crucial to develop high-performance carbon capture membranes that reduce the energy consumption and the associated cost of carbon capture from point-emission sources. Indeed, techno-economic assessments of the capture process based on high-performance PG membranes indicate that the energy efficiency of capture can be substantially improved compared with the commercial amine-based absorption process. This is mainly because the membrane processes do not require thermal energy but rather rely on electrical energy for feed compression and permeate evacuation. This is also because PG membranes yield extremely high CO2 permeance resulting from their atom-thin selective layer. This minimizes the required membrane area and the capture process footprint. This, combined with the exceptional chemical stability of graphene, makes capture based on PG membranes advantageous for carbon capture compared with the state-of-the-art membranes based on polymers, zeolites, metal–organic frameworks, covalent organic frameworks and carbon molecular sieves. A low-footprint capture process is attractive for application in the transportation sector, especially the international shipping industry, responsible for 2–3% of global CO2 emissions.

An early proof-of-concept study on the selective transport of CO2 from PG was demonstrated by Bunch and coworkers in 2012 (ref. 2). This was a fundamental study from a micrometer-sized exfoliated graphene with only a couple of pores responsible for gas transport. However, for practical membranes, one must prepare macroscopic films. For this, polycrystalline graphene, produced by chemical vapor deposition (CVD) on Cu foil, has become a standard material24,25,26. Yet, it is challenging to prepare a large-area PG membrane. Several aspects of the PG membrane must be debottlenecked to become commercially attractive for carbon capture. This includes the reduction of membrane element cost, the scalable incorporation of CO2-selective pores in graphene and the crack-free fabrication of membranes. These challenges are elaborated below.

Currently, the cost of commercial CVD graphene is extremely high for its application in carbon capture membranes. It is unclear whether low-cost Cu foils (approximately US$10 m−2), which contain micrometer-sized particulate contaminations from rough processing, can be suitable for producing graphene for CO2-selective membranes. This is mainly because strict control of substrate smoothness and particulate contaminations is needed to achieve attractive CO2/N2selectivity given the sub-ångström difference in the size of the two molecules. Literature studies often use expensive Cu foils (US$500–10,000 m−2) or delicate processing methods (for example, electropolishing) to prepare high-performance graphene membranes for carbon capture. This high raw material cost is prohibitive for the carbon capture application. By comparison, polymeric membranes for carbon capture have a membrane element cost of US$20–50 m−2. Incidentally, the major cost of CVD graphene is related to the expensive Cu foil. However, Cu foils are also produced cheaply (approximately US$10 m−2). An important challenge here is that low-cost Cu foils have surface imperfections in the form of micrometer-sized particles and large grooves and scratches. These imperfections are detrimental to the fabrication of high-quality graphene membranes for carbon capture because they compromise the integrity of the suspended graphene by generating cracks.

The second challenge concerns the lack of demonstration of CO2-selective pore incorporation in graphene over a large area. Pores in graphene are carbon vacancy defects incorporated by removing atoms from the basal plane. Chemical routes involving the gasification of the lattice by oxidation are intrinsically more scalable than carbon-knockout routes using energetic beams. For oxidation, oxidative plasma, oxygen (O2), ultraviolet light/ozone (O3) or O3 have been demonstrated. However, they involved sophisticated setups that are challenging to scale up. The uniformity of pore incorporation over a large area is not demonstrated.

The third challenge relates to fabricating large-area PG membranes while avoiding cracks in graphene. Cracks typically manifest during the transfer of CVD graphene from the Cu foil to porous support or during pressurization of the PG membrane. Wafer-scale and roll-to-roll transfer have been demonstrated in fabricating graphene devices for electronic applications. However, while these applications are tolerant to macroscopic cracks in graphene, gas separation membranes are not. Crack-free PG is essential for selective transport between similarly sized gas molecules such as CO2 and N2 under pressurized conditions. Centimeter-scale PG membranes have been demonstrated for nanofiltration after stitching cracks using interfacial polymerization. However, this approach has not been demonstrated for gas separation. Prior works have shown that cracks in PG can be avoided by using gas-permeable mechanically reinforcing support film (MRF). Typically, MRF is deposited on PG, and the Cu foil is removed by wet-chemical etching, after which the floating composite PG–MRF is scooped on the desired porous support. MRF can be a nanoporous carbon (NPC) film, highly permeable polymers such as poly[1-(trimethylsilyl)-1-propyne] (PTMSP), polydimethylsiloxane or a composite film such as multiwalled carbon nanotube deposited on NPC. However, the success rate of achieving centimeter-scale gas-selective membranes (defined as the number of selective membranes normalized by the number of attempts), even using the MRF strategy, remains low. This is mainly because the transfer protocol involves floating and scooping steps where cracks can easily develop in PG. Transfer methods involving careful scooping of floating PG are also extremely challenging to scale up. Therefore, a key challenge is to develop a membrane fabrication route avoiding careful scooping of graphene, and where the success rate is nearly 100%.

Here, we present several advances toward scaling up PG membranes for carbon capture. We demonstrate the successful use of a low-cost Cu foil (US$10 m−2) to prepare PG membranes with attractive CO2/N2 separation performance with a near 100% success rate. A simple protocol was developed to eliminate large contaminant particles on the surface of low-cost Cu foil. A large reactor for pore incorporation was implemented, which allowed the incorporation of uniform pores in large-area graphene (500 cm2) in a reproducible manner. A systematic study of graphene oxidation revealed that O3 mass transfer (velocity), as opposed to the commonly studied reaction kinetics (temperature and time), dominates pore formation kinetics. A facile and user-friendly transfer protocol was developed, completely avoiding the floating step, resulting in a highly reproducible synthesis. These interventions yielded attractive performance with a near 100% success rate from PG membranes.

- First-in-human Controlled Inhalation of Thin Graphene Oxide Nanosheets to Study Acute Cardiorespiratory Responses

Nature Nanotechnology

Volume 19

pages 705–714 (2024)

Author: Jack P. M. Andrews, Shruti S. Joshi, Evangelos Tzolos, Maaz B. Syed, Hayley Cuthbert, Livia E. Crica, Neus Lozano, Emmanuel Okwelogu, Jennifer B. Raftis, Lorraine Bruce, Craig A. Poland, Rodger Duffin, Paul H. B. Fokkens, A. John F. Boere, Daan L. A. C. Leseman, Ian L. Megson, Phil D. Whitfield, Kerstin Ziegler, Seshu Tammireddy, Marilena Hadjidemetriou, Cyrill Bussy, Flemming R. Cassee, David E. Newby, Kostas Kostarelos & Mark R. Miller

Abstract

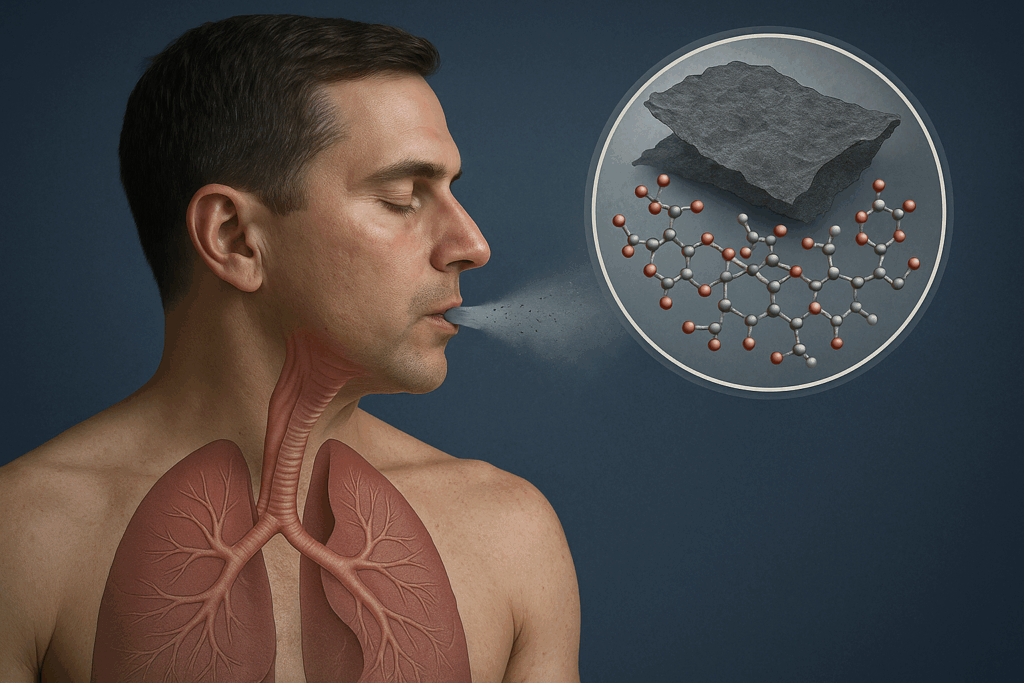

Graphene oxide nanomaterials are being developed for wide-ranging applications but are associated with potential safety concerns for human health. We conducted a double-blind randomized controlled study to determine how the inhalation of graphene oxide nanosheets affects acute pulmonary and cardiovascular function. Small and ultrasmall graphene oxide nanosheets at a concentration of 200 μg m−3 or filtered air were inhaled for 2 h by 14 young healthy volunteers in repeated visits. Overall, graphene oxide nanosheet exposure was well tolerated with no adverse effects. Heart rate, blood pressure, lung function and inflammatory markers were unaffected irrespective of graphene oxide particle size. Highly enriched blood proteomics analysis revealed very few differential plasma proteins and thrombus formation was mildly increased in an ex vivo model of arterial injury. Overall, acute inhalation of highly purified and thin nanometre-sized graphene oxide nanosheets was not associated with overt detrimental effects in healthy humans. These findings demonstrate the feasibility of carefully controlled human exposures at a clinical setting for risk assessment of graphene oxide, and lay the foundations for investigating the effects of other two-dimensional nanomaterials in humans. Clinicaltrials.gov ref: NCT03659864.

Main

Two-dimensional (2D) nanomaterials are defined as flat, non-spherically shaped substances with a least one dimension <100 nm, and have generated worldwide interest for a variety of potential applications including building materials, car tyres, inks, food preservatives, sun-screens and anti-corrosion and lubricating products. Graphene is an archetypal 2D nanomaterial of a single layer or few layers of carbon lattice. Its unique structure, strength, flexibility, transparency and electrical conductance properties make it attractive for a wide range of applications. There is also intense interest in further developing such materials for biomedical applications, including diagnostic and drug-delivery agents. The oxidized form of graphene, graphene oxide (GO), has shown promise in the biomedical setting due to its hydrophilicity, high surface area for chemical functionalization, reasonable colloidal stability in biologically relevant solutions and compatibility with blood cells. However, like other manufactured nanomaterials, the safety profile and limitations of GO on human exposure need to be determined before widespread use. There are limited and inconsistent toxicological data available for GO, often arising from differences among the many different sources of the material and their notable variability in dimensions and chemical properties that do not allow confident conclusions to be reached regarding its safety. We have systematically synthesized GO nanosheets with high control and homogeneity of size and minimal trace metal and no endotoxin contaminations that do not exert the overt toxicity reported for many commercial sources of other graphene material types (such as graphene nanoplatelets). These highly purified GO materials have been thoroughly investigated using in vitro and in vivo models by different laboratories during the past decade. A recent repeated and long-term pulmonary exposure study of these GO nanosheets in mice found that large (micrometre range) lateral size and high doses induced pulmonary inflammation (although substantially less than long, rigid carbon nanotubes) and more persistent granulomas. Smaller (nanometre range) GO nanosheet exposures have demonstrated a transient inflammatory response that resolved rapidly post-exposure.

Parallels can be drawn between manufactured nanomaterials and the small particulate matter in air pollution. Particulate matter exposure has been linked to adverse health effects in almost every organ of the body, although the respiratory and cardiovascular effects drive the substantial morbidity and mortality associated with particulate matter. Ultrafine (nano-sized) particulate matter is likely to contribute to these effects, given the high deposition in the alveoli of the lungs, the high reactive surface area for a given mass and the penetration to systemic organs. While different classes of manufactured nanomaterial have distinct properties, there are commonalities with ultrafine particulate matter with respect to some physiochemical features and the pathways by which they induce toxicological effects, such as inflammation and oxidative stress. Although there is an expanse of large-cohort epidemiological data linking particulate matter in air pollution with adverse effects, human data on the biological actions of manufactured nanomaterials are confined to cultures of human cell lines and biomonitoring in occupational settings or isolated accidental exposures in small groups of individuals. Inhalation is the primary route of unintended pulmonary exposure to manufactured nanomaterials, but it also represents a promising route of administration for nanomedicines used for diagnosis and drug delivery for respiratory conditions. Therefore, human data are urgently needed to assess risk assessment and realize the true potential of these materials.

Controlled human exposure studies offer several advantages for assessing the acute biological effects of xenobiotics. Unlike epidemiological studies, substances can be tested in isolation at defined doses. Real-world confounders, such as other environmental stressors (for example noise, stress, heat, exercise or medication) can be minimized or standardized across participants and study visits. The design can be tailored to include relevant control exposures, with repeated measure designs allowing each participant to be their own control. The use of a controlled exposure environment at clinics or laboratory facilities can broaden the range of endpoints to include a greater range of subclinical and mechanistic endpoints and has been used successfully to determine the respiratory and cardiovascular effects of combustion-derived nanoparticles such as those in diesel exhaust emissions. However, only a handful of studies have tested the actions of manufactured nanomaterials, and no studies have been performed with non-spherical materials such as graphene.

In this study we aimed to understand the potential for GO to have detrimental health effects, principally from the viewpoint of unintended exposure (for example occupationally or from public exposure with increasing use of nanomaterials in real-world applications) but also from the perspective of the development of safe forms of GO for intended human exposure by inhalation (for example for diagnostic imaging of the lung or drug delivery to or via the lung). Using a randomized controlled double-blind crossover design, we investigated the cardiorespiratory effects of acute inhalation of GO nanosheets in human volunteers. We hypothesized that inhalation of our high-purity, thin GO would have only modest effects on cardiorespiratory function and blood markers of inflammation and coagulability, the magnitude of which would be lower the smaller the lateral dimensions of the nanosheets. The findings of this controlled human inhalation exposure to GO in human volunteers lay the foundations for future investigations to establish which properties of graphene materials determine their biological actions to provide a formal risk assessment and allow safe-and-sustainable-by-design development for various applications.

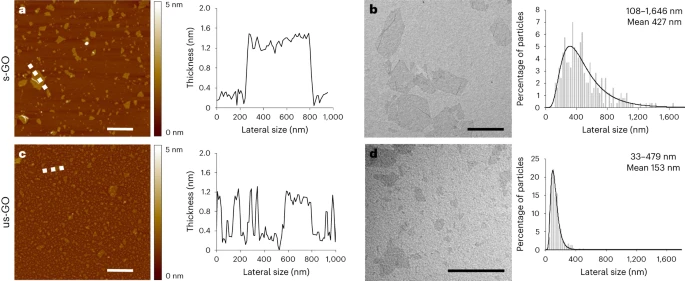

Synthesis and Characterization of GO Nanosheets

Thin, highly purified metal-free and endotoxin-free GO materials were synthesized using a modified Hummers’ method and comprehensively characterized (Fig. 1, Extended Data Table 1 and Extended Data Fig. 1). GO nanosheets were of tightly defined size, with no metallic or other elemental contamination, residues or indicators of bacterial contamination. Two lateral dimensions (maintaining all other physicochemical characteristics almost identical) were selected for the study: small GO (s-GO) and ultrasmall GO (us-GO). Both types of nanosheet have demonstrated no acute or longitudinal adverse effects in our previous pre-clinical (rodent) studies, contrary to ‘large’ GO sheets that were thus excluded from this work as a safety precaution.

Fig. 1: GO Nanosheet Size Distributions

a–d, Morphological characterizations of s-GO (a,b) and us-GO (c,d). The images (left) and spectra (right) are representative of the technical replicates performed. Atomic force microscopy height images (left; a and c) with the corresponding cross-section analysis along the indicated dashed white lines (right; a and c). The colour bars indicate the height intensity range from 0 to 5 nm. Transmission electron microscopy micrographs (left; b and d) with the size distribution analyses using a Gaussian single peak fitting depicted with solid lines (right; b and d) are shown. Scale bars are 1 µm. The lateral size range and means given in b and d are an average of 242 and 224 individual GO sheets, respectively (see a summary table in Extended Data Table 1).

GO nanosheets were aerosolized for exposure of volunteers through inhalation via a face mask with a target mass concentration of 200 μg m−3. The actual concentrations of s-GO and us-GO were 214 ± 23 μg m−3 and 224 ± 17 μg m−3, respectively (Extended Data Table 2) and were maintained at a constant level throughout the 2 h exposure (Supplementary Fig. 1a). As anticipated, the us-GO had a greater particle number than the s-GO for the same mass. The GO agglomerated to airborne sizes with a median value of 80–90 nm and a high size distribution homogeneity (Supplementary Fig. 1b). The levels of GO used here (200 μg m−3) were substantially higher than concentrations of graphene materials found in many workplaces that handle/process these materials (0.4–50 μg m−3) and are relevant to proposed occupational guidance for graphene nanoplatelets (212 μg m−3).

- Advanced Therapeutics Volume 3, Issue 3

A Graphene-Based Flexible Device as a Specific Far-Infrared Emitter for Noninvasive Tumor Therapy

Volume3, Issue3

March 2020

1900195

Author: Tingting Yu, Yimin Hu, Guanping Feng, Ke Hu

Abstract

Noninvasive treatments are emerging as a promising strategy not only due to their non-invasive nature, but also due to their additive effects to traditional radiotherapy and chemotherapy. Herein, specific far-infrared rays generated from single-layer, graphene-based devices are applied to tumors as a novel noninvasive therapeutic strategy. In MDA-MB-231 breast cancer cell xenograft and metastasis models, irradiation generated from this flexible device reduces the rate of tumor growth and the number of metastatic nodules per lung by 42% and 55%, respectively. This result might be induced by the similarity between the emission spectra of the device and the absorption spectra of the living tissue. With its high energy conversion and safety, the graphene-based device can serve as an adjuvant therapeutic instrument for combined tumor treatment.

- Macro Molecular Bioscience Volume 22, Issue 4

Evaluation of an Injectable Hydrogel Based on Hyaluronic Acid–Chitosan/β-Glycerophosphate-Loaded Mesenchymal Stem Cells in Enhancing the Therapeutic Efficacy of Myocardial Infarction

Volume 22, Issue 4

April 2022

2100286

Author: Liang Peng, Muwei Li, Kang Zhao, Cao Ma, Haiyu Tang, Yan Li

Abstract

Myocardial infarction (MI), which is due to cardiac dysfunction, results in morbidity and mortality. Moreover, the cellular activity of transplanted mesenchymal stem cells (MSCs) generally limits their therapeutic efficacy in the treatment of MI. Here, inject able hyaluronic acid-chitosan/β-glycerophosphate (HA–CS/β-GP) hydrogel-loaded MSCs are prepared, after which their effects on the treatment of MI are investigated. The synthesized HA–CS/β-GP hydrogels exhibit swelling ratio, an in vitro degradation value, and a gelatin time of 82.19 ± 4.1, 88.18% ± 2.4%, and 9 s, respectively. Further, rheological studies revealed that the elastic modulus of the HA–CS/β-GP hydrogels is ≥230 Pa, exhibiting large elastic to viscous modulus ratio, which indicates their mechanical strength. Furthermore, the in vitro 3T3 cell and MSC culture studies confirm the good biocompatibility of the HA–CS and HA–CS/β-GP hydrogels. The implantation of the synthesized hydrogels in the mouse MI model considerably improves the therapeutic effect of the MSCs (enhanced cardiac function, reduced cardiomyocyte apoptosis, and increased vascularization) for the first time. The innovative synergistic strategy of combining injectable HA–CS and HA–CS/β-GP hydro gels with MSCs may be suitable for the effective treatment of cardiac morbidity due to MIs.

- Pioneer of Graphene: Professor Feng Guanping’s Vision for the Future of Global Innovation

In 2009, Professor Feng Guanping united a team of overseas Chinese graphene experts and invested initial capital to incubate more than 20 graphene companies. Under his leadership, the graphene industry chain in China was successfully formed and developed, earning him the widely recognized title of “Pioneer of the Graphene Industry.”

As the founder of Xiwang New Material Technology Co., Ltd., Professor Feng holds numerous prestigious positions, including Chairman of Xiwang Technology, Founding Dean of the Shenzhen Tsinghua University Research Institute, and Honorary Chairman of the Jiangnan Graphene Research Institute. He also serves as an expert at the International Graphene Innovation Center and as President of the Shenzhen Graphene Association.

His groundbreaking contributions have earned national recognition. Professor Feng has received the State Council Special Allowance, the Shenzhen “Mayor Award”, and the Commemorative Medal for the 70th Anniversary of the Founding of the People’s Republic of China, awarded by the Central Committee of the Communist Party of China, the State Council, and the Central Military Commission. In 2020, he was named one of the “40 Innovators and Exemplary Figures” in celebration of the 40th anniversary of the Shenzhen Special Economic Zone.

A Legacy of Scientific Achievement and Industry Impact

Professor Feng’s influence extends beyond innovation into industrial transformation. His work has supported:

- Over 1000 graphene-incubated companies

- More than 20 listed enterprises

- 22 national patents

- 14 provincial-level technological achievements

- 5 national-level innovation awards

He has also been honored with lifetime achievement awards from the IGA International Graphene Association, served as chairman of the International Graphene Innovation Conference, and was listed among China’s Top 10 Investment Leaders.

Through decades of dedication, Professor Feng Guanping has led the integration of graphene technology into practical applications, building a strong foundation for China’s leadership in new material industries. His continuing role in the Metatoz ecosystem ensures that cutting-edge innovation remains at the heart of everything we do.