Nature Chemical Engineering

(2025)

Author: Jian Hao, Piotr Mieczyslaw Gebolis, Piotr Marcin Gach, Mojtaba Chevalier, Luc Sébastien Bondaz, Ceren Kocaman, Kuang-Jung Hsu, Kapil Bhorkar, Deep J. Babu & Kumar Varoon Agrawal

Abstract

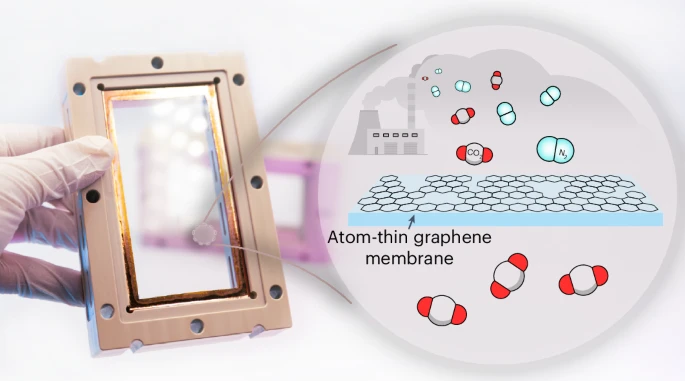

Membranes based on atom-thin porous single-layer graphene (PG) have shown attractive performance for diverse separation applications, especially gas separation and carbon capture. However, despite a decade of research, a scalable synthesis of PG membranes has remained under question. The literature on gas separation using porous graphene membranes is based on complex methods that limit membrane size and reproducibility. Here we introduce several interventions that substantially reduce PG membrane cost, allow uniform pore formation in a large area and enable the preparation of large-area PG membranes with attractive performance. We show that mass transfer of the oxidant plays a crucial role in achieving uniform oxidation of large-area graphene. Crack formation during the transfer of graphene, which also limits reproducibility, is eliminated using a protocol that does not require delicate floating and handling of graphene, allowing the realization of a high-performance 50-cm2 graphene membrane in a cross-flow module.

Main

Nanoporous atomically thin membranes (NATMs) have emerged as a promising platform for effectively separating molecules and ions, exploiting mass, size and affinity differences. Despite progress on the fundamental aspects of NATM, including transport mechanism, pore incorporation and membrane fabrication, this field faces an outstanding critical challenge on the scalability of NATMs. The most popular and studied NATM is porous single-layer graphene (PG). The successful incorporation of carbon dioxide (CO2)-selective pores in PG has led to attractive performance for carbon capture. This involves selective separation of CO2 from nitrogen (N2). It is crucial to develop high-performance carbon capture membranes that reduce the energy consumption and the associated cost of carbon capture from point-emission sources. Indeed, techno-economic assessments of the capture process based on high-performance PG membranes indicate that the energy efficiency of capture can be substantially improved compared with the commercial amine-based absorption process. This is mainly because the membrane processes do not require thermal energy but rather rely on electrical energy for feed compression and permeate evacuation. This is also because PG membranes yield extremely high CO2 permeance resulting from their atom-thin selective layer. This minimizes the required membrane area and the capture process footprint. This, combined with the exceptional chemical stability of graphene, makes capture based on PG membranes advantageous for carbon capture compared with the state-of-the-art membranes based on polymers, zeolites, metal–organic frameworks, covalent organic frameworks and carbon molecular sieves. A low-footprint capture process is attractive for application in the transportation sector, especially the international shipping industry, responsible for 2–3% of global CO2 emissions.

An early proof-of-concept study on the selective transport of CO2 from PG was demonstrated by Bunch and coworkers in 2012 (ref. 2). This was a fundamental study from a micrometer-sized exfoliated graphene with only a couple of pores responsible for gas transport. However, for practical membranes, one must prepare macroscopic films. For this, polycrystalline graphene, produced by chemical vapor deposition (CVD) on Cu foil, has become a standard material24,25,26. Yet, it is challenging to prepare a large-area PG membrane. Several aspects of the PG membrane must be debottlenecked to become commercially attractive for carbon capture. This includes the reduction of membrane element cost, the scalable incorporation of CO2-selective pores in graphene and the crack-free fabrication of membranes. These challenges are elaborated below.

Currently, the cost of commercial CVD graphene is extremely high for its application in carbon capture membranes. It is unclear whether low-cost Cu foils (approximately US$10 m−2), which contain micrometer-sized particulate contaminations from rough processing, can be suitable for producing graphene for CO2-selective membranes. This is mainly because strict control of substrate smoothness and particulate contaminations is needed to achieve attractive CO2/N2selectivity given the sub-ångström difference in the size of the two molecules. Literature studies often use expensive Cu foils (US$500–10,000 m−2) or delicate processing methods (for example, electropolishing) to prepare high-performance graphene membranes for carbon capture. This high raw material cost is prohibitive for the carbon capture application. By comparison, polymeric membranes for carbon capture have a membrane element cost of US$20–50 m−2. Incidentally, the major cost of CVD graphene is related to the expensive Cu foil. However, Cu foils are also produced cheaply (approximately US$10 m−2). An important challenge here is that low-cost Cu foils have surface imperfections in the form of micrometer-sized particles and large grooves and scratches. These imperfections are detrimental to the fabrication of high-quality graphene membranes for carbon capture because they compromise the integrity of the suspended graphene by generating cracks.

The second challenge concerns the lack of demonstration of CO2-selective pore incorporation in graphene over a large area. Pores in graphene are carbon vacancy defects incorporated by removing atoms from the basal plane. Chemical routes involving the gasification of the lattice by oxidation are intrinsically more scalable than carbon-knockout routes using energetic beams. For oxidation, oxidative plasma, oxygen (O2), ultraviolet light/ozone (O3) or O3 have been demonstrated. However, they involved sophisticated setups that are challenging to scale up. The uniformity of pore incorporation over a large area is not demonstrated.

The third challenge relates to fabricating large-area PG membranes while avoiding cracks in graphene. Cracks typically manifest during the transfer of CVD graphene from the Cu foil to porous support or during pressurization of the PG membrane. Wafer-scale and roll-to-roll transfer have been demonstrated in fabricating graphene devices for electronic applications. However, while these applications are tolerant to macroscopic cracks in graphene, gas separation membranes are not. Crack-free PG is essential for selective transport between similarly sized gas molecules such as CO2 and N2 under pressurized conditions. Centimeter-scale PG membranes have been demonstrated for nanofiltration after stitching cracks using interfacial polymerization. However, this approach has not been demonstrated for gas separation. Prior works have shown that cracks in PG can be avoided by using gas-permeable mechanically reinforcing support film (MRF). Typically, MRF is deposited on PG, and the Cu foil is removed by wet-chemical etching, after which the floating composite PG–MRF is scooped on the desired porous support. MRF can be a nanoporous carbon (NPC) film, highly permeable polymers such as poly[1-(trimethylsilyl)-1-propyne] (PTMSP), polydimethylsiloxane or a composite film such as multiwalled carbon nanotube deposited on NPC. However, the success rate of achieving centimeter-scale gas-selective membranes (defined as the number of selective membranes normalized by the number of attempts), even using the MRF strategy, remains low. This is mainly because the transfer protocol involves floating and scooping steps where cracks can easily develop in PG. Transfer methods involving careful scooping of floating PG are also extremely challenging to scale up. Therefore, a key challenge is to develop a membrane fabrication route avoiding careful scooping of graphene, and where the success rate is nearly 100%.

Here, we present several advances toward scaling up PG membranes for carbon capture. We demonstrate the successful use of a low-cost Cu foil (US$10 m−2) to prepare PG membranes with attractive CO2/N2 separation performance with a near 100% success rate. A simple protocol was developed to eliminate large contaminant particles on the surface of low-cost Cu foil. A large reactor for pore incorporation was implemented, which allowed the incorporation of uniform pores in large-area graphene (500 cm2) in a reproducible manner. A systematic study of graphene oxidation revealed that O3 mass transfer (velocity), as opposed to the commonly studied reaction kinetics (temperature and time), dominates pore formation kinetics. A facile and user-friendly transfer protocol was developed, completely avoiding the floating step, resulting in a highly reproducible synthesis. These interventions yielded attractive performance with a near 100% success rate from PG membranes.